The hose injection head machine is mainly used in the injection molding production of packaging hose shoulder. The b.gls-iii injection head machine produced by our company has fast manufacturing speed, high degree of full automation, stable performance and no pollution in the production process. It can create high benefits for the majority of hose manufacturers and daily chemical products manufacturers.

Compared with other models at home and abroad, our full-automatic injection head machine has the following advantages:

1. All actions of the hose injector are controlled by PLC servo, with low pneumatic requirements and stable operation.

2. It integrates water and electricity, with high manufacturing efficiency, low energy consumption, simple operation, automatic fault alarm and no three wastes.

3. Full mold is selected, the hose shoulder is seamless, beautiful and stable.

4. The rotary table and other key parts are mainly made of manganese magnesium alloy. The material is light and stable, which is conducive to the long-term operation of the machine.

5. The main parts of the machine are imported accessories.

The hose injection head machine mainly includes: gap indexing operation mechanism, automatic pipe feeding mechanism, quantitative plastic spitting mechanism, mold closing and forming mechanism, demoulding and separation mechanism, automatic pipe unloading mechanism, automatic feeding mechanism, buffer pipe storage box, etc.

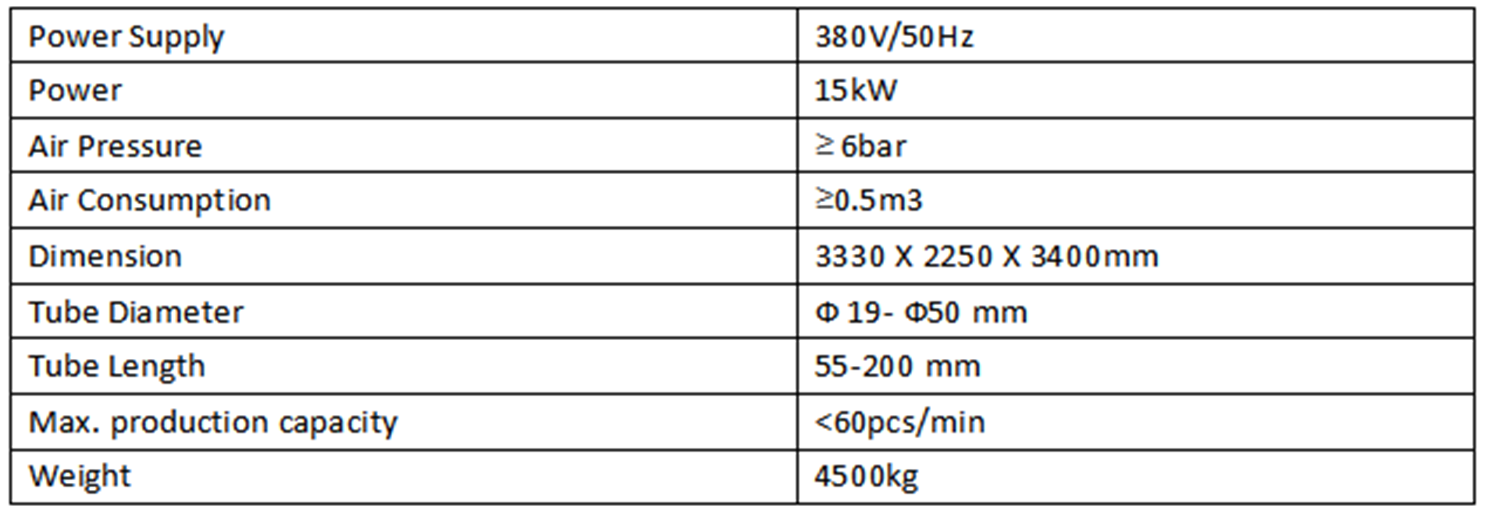

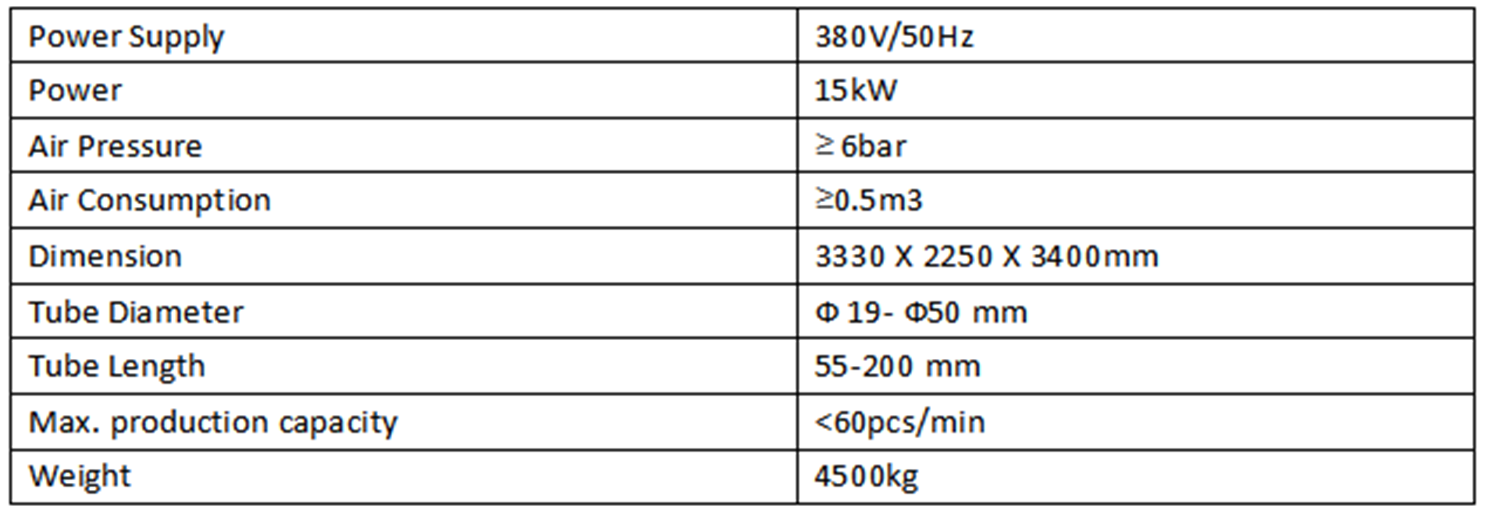

Main technical parameters: