Shoulder injection machine and mould

Double mode alternating forming is selected, with high production efficiency; Screw pre molding, quantitative, limit feeding, full hydraulic fast and slow mold closing are selected. Large mold locking force, stable mold movement, electrical interlocking,

Double mode alternating forming is selected, with high production efficiency; Screw pre molding, quantitative, limit feeding, full hydraulic fast and slow mold closing are selected. Large mold locking force, stable mold movement, electrical interlocking, smooth, beautiful and reliable injection head; Small footprint; The mould has the advantages of convenient disassembly and assembly.

Shoulder mold: the diameter of the pipe is 12.7mm -- 60mm; The shapes are oval and round, which can also be designed and manufactured according to customer needs; Thread shape can also be designed and manufactured according to customer requirements.

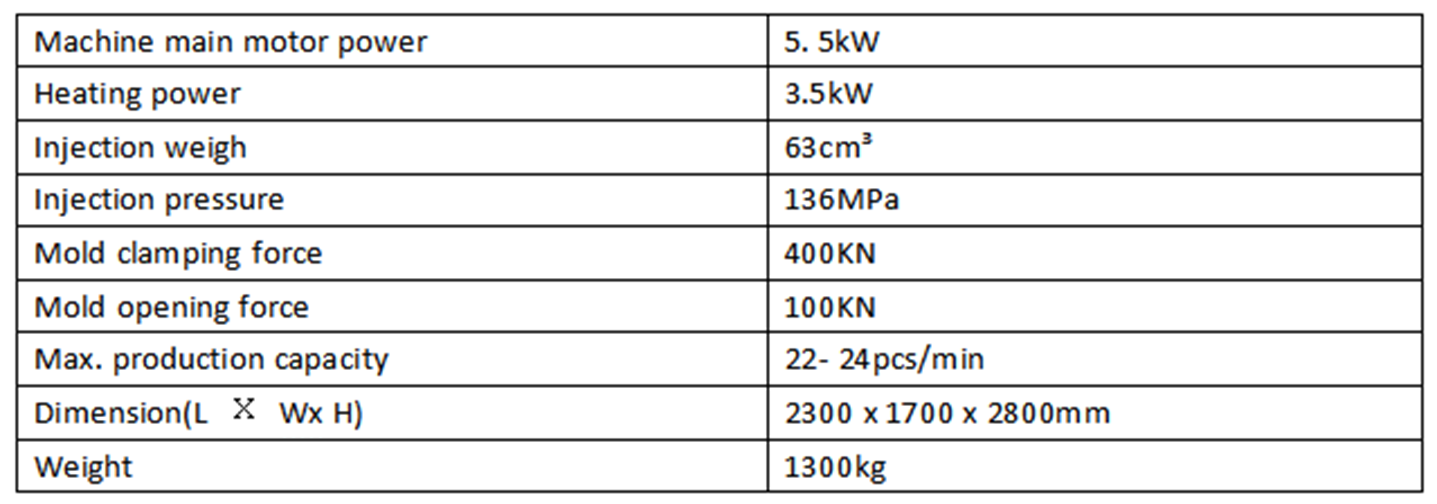

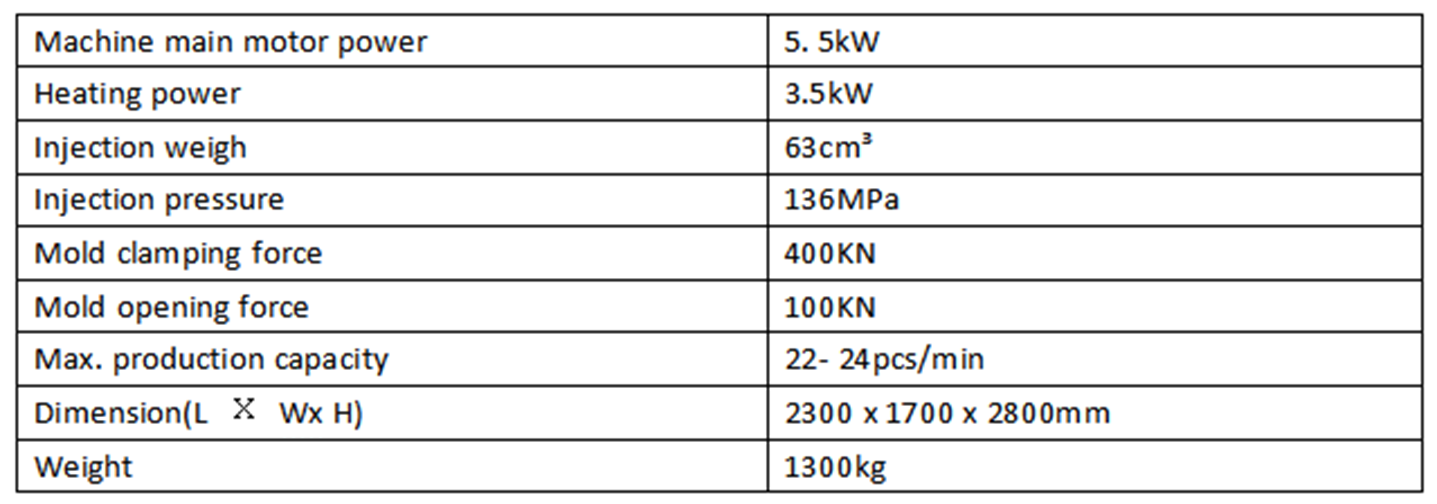

Main technical parameters: