This facility is widely used in cosmetics, toothpaste, medical creams, food, shoe polish, viscose and other industries. It is suitable for canning, tail sealing and batch number printing of aluminum plastic and all plastic hose packaging products. According to the needs of customers, this facility can specially formulate and adopt special canning devices, which can realize the dual-purpose canning of liquid materials and cream materials. The facility can be used independently, and can also form a production line with automatic packaging machines and other facilities.

advantage

1. The main drive is of full mechanical structure, with stable operation, low noise and convenient operation and maintenance;

1. Equipped with automatic pipe dropping box, automatic pipe feeding, automatic color code matching and automatic pipe outlet;

3. The hot air is heated in the hot air, and the hot air is heated from the inner wall of the pipe, which does not damage the surface organization of the hose. The tail sealing is beautiful and generous. It is very suitable for the tail sealing of all plastic packaging hose.

4. Automatic adjustment of filling capacity, no filling without pipe, PLC control and touch screen operation.

5. Equipped with plexiglass dust cover;

6. Special shaped tail sealing; (optional)

7. Anti wire drawing or anti drip canned head; (optional)

8. Liquid level control and alarm system of storage barrel, automatic feeding; (optional)

9. With mixing storage barrel; (optional)

10. With heated storage bucket. (optional)

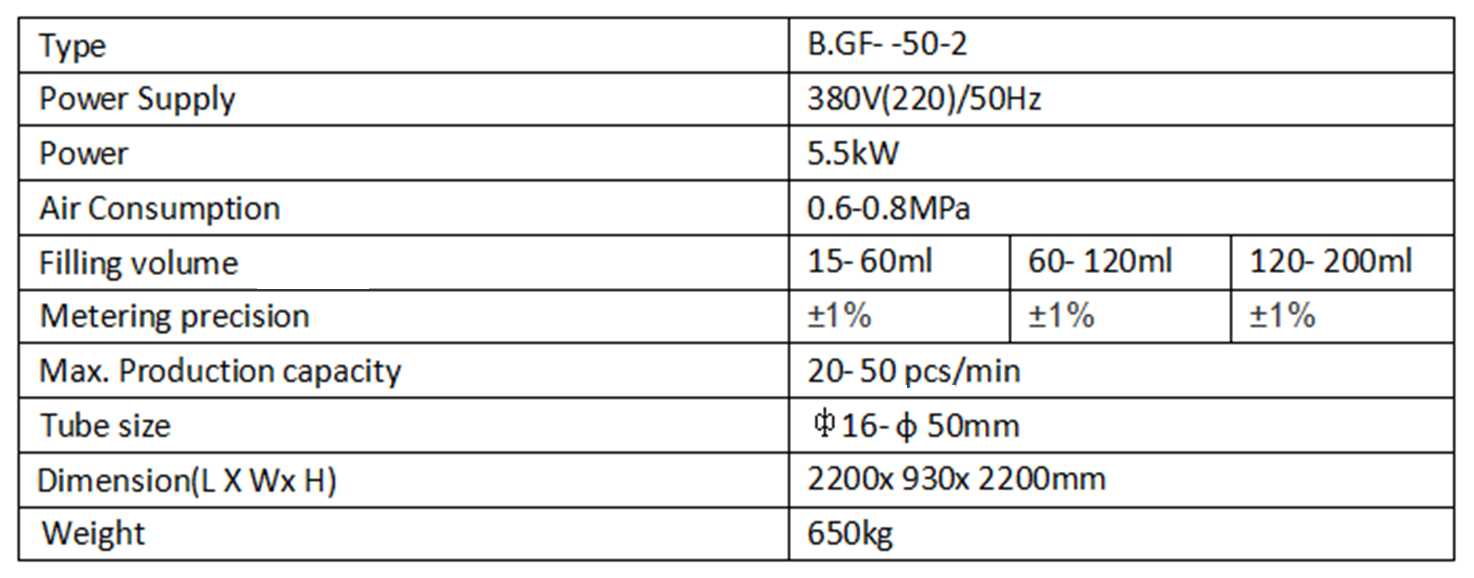

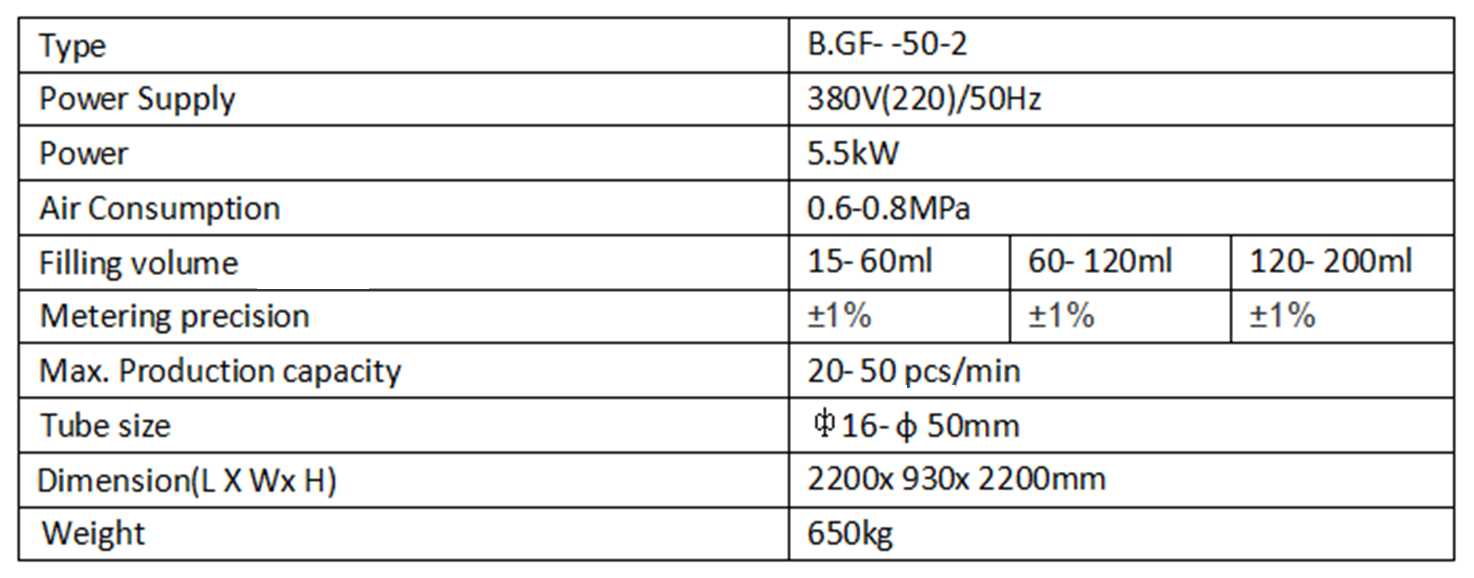

Main technical parameters: